Velodyne, largely considered the current leader in LiDAR tech for autonomous vehicle development, announced today that it has increased its production capacity by more than 400 percent in order to meet growing global demand. This means it’s now actually offering immediate availability for its LiDAR sensors, for the first time in a long time, for clients in Europe, Asia Pacific and North America.

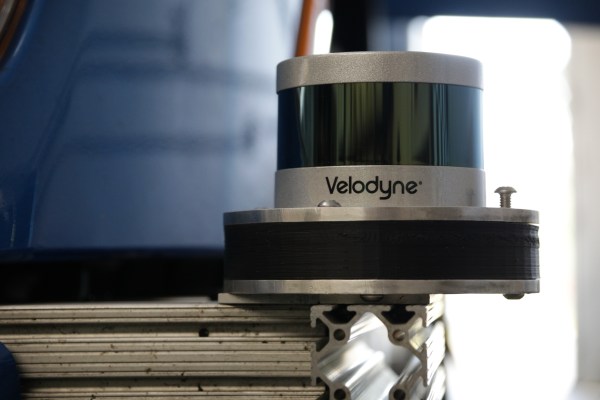

This new capacity has come from a boosted production rate at Velodyne’s gigantic 200,000 square foot Megafactory, and it has doubled its full-time employee count over the past six months as well to help spur production. Velodyne’s HDL-32/64 LiDARs, the classic ‘chicken bucket’ design you’ve likely seen on autonomous test vehicles in media photos or out in the real world, is the industry standard at the moment, with relatively few competitors even approaching the company in terms of production capability.

Velodyne has some emerging competitors, however, including startup Luminar, which emerged from stealth with a large workforce and production-ready design earlier this year. But it’s also working on new versions of its own LiDAR which will decrease cost and conspicuousness on a path toward production AVs.