“You don’t just hand over a prototype to manufacturing and say, ‘make this,’ ” Maxwell Bogue explains, offering some off-hand advice to hardware startups. “Whatever you made is wrong. It’s just not mass producible, as much you think it is.”

He speaks from experience. The first time I met Wobbleworks’ CEO, his office was a small cube in a Massachusetts maker space , packed full of robot toys in various stages of deconstruction. He and partner Peter Dilworth paraded their project out, showing them off to our cameras one by one, culminating with Flap-Itz, a $10 pair of plastic animal ears that bob up and down, courtesy of a small hydraulic hand pump.

After that interview, Bogue added something about a “secret project.” Something he couldn’t yet tell me about – but something that would be huge nonetheless. That’s what they all say.

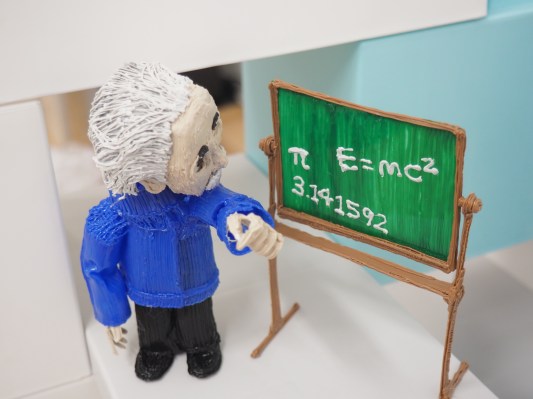

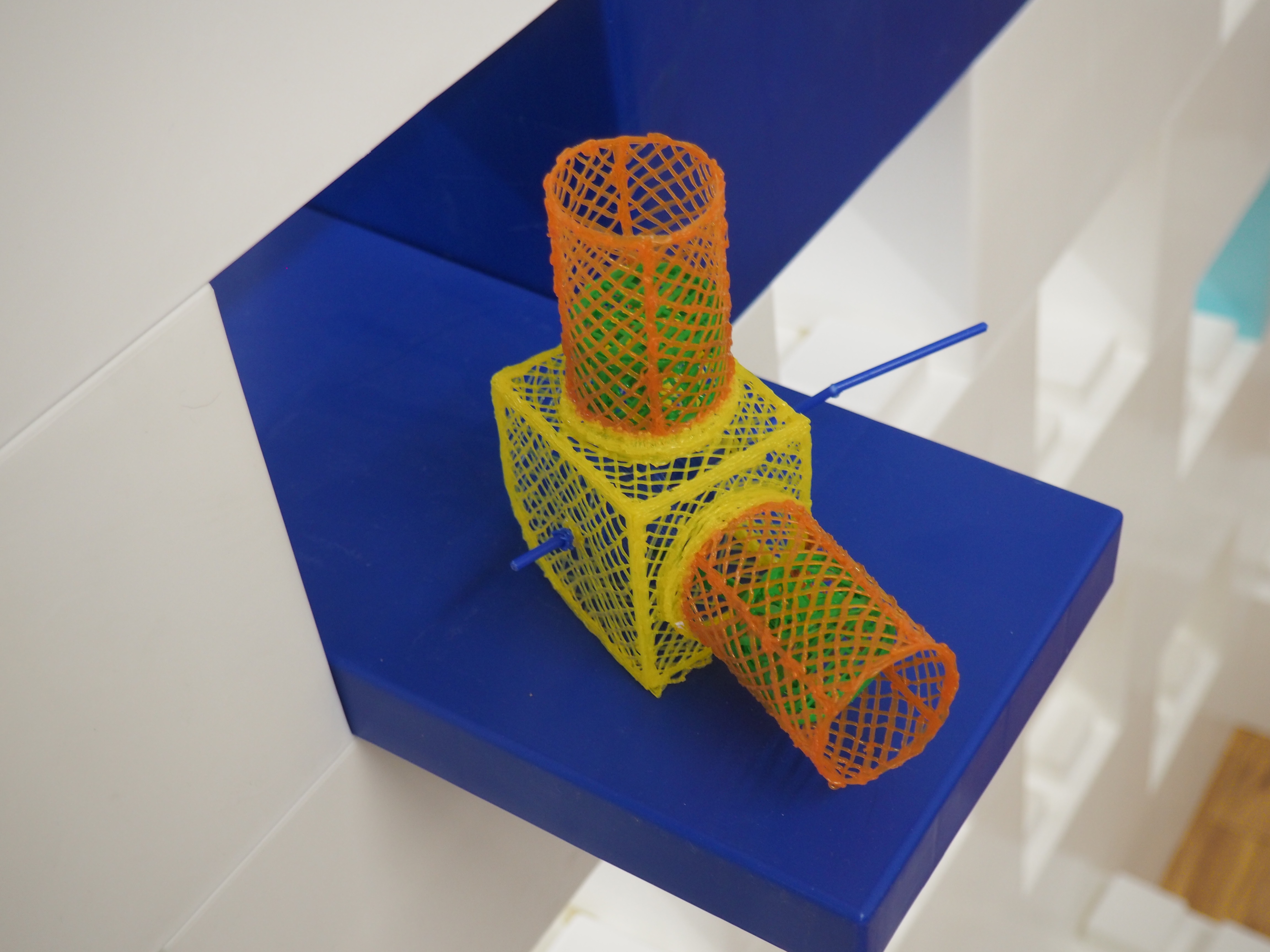

The product was the 3Doodler. A 3D printing pen that managed to score $3.2 million on Kickstarter, when such a feat will still a major novelty. Four years later, the product is on its fourth generation. It’s scored the company distribution from major retailers like Staples, Michael’s and Best Buy, and inspired fine artists to adopt the silly but compelling medium that allows from drawing in the air.

Recently the company set up another satellite office in Manhattan. It’s a small unassuming space, aside from the makeshift conference room the team constructed from giant Lego-style blocks and, of course, the piles and piles of colorful plastic filament lining the walls.

Bogue attributes the company’s success, in part, to good timing. “If 3D printing hadn’t been so popular with the public,” he explains, “if there hadn’t been so many successful Kickstarter campaigns, I think it probably would have been more flat.”

Having two toy industry veterans didn’t hurt, either. Both spent time a number of toy companies – most notable WowWee, where Bogue served as R&D Project Manager, a key factor in helping the fledgling company make the often treacherous step from Kickstarter success to actual product.

“The best advice I can give to someone who wants to bring a product to market is go work for a company that does that,” says Bogue. “Spend a couple of years in someone else’s employment, learning how that whole world works. Then take your product to market. You’ll have a much easier time. You’ll create a contact list, you’ll understand the process better.”

While many manufacturers have shifted to accommodate the new crowdfunded economy, the system isn’t exactly made-to-order. “If you have no exposure to this world, then most likely the pricing that you’ve drawn out of the air probably won’t be right,” says Bogue. “Going to RadioShack and grabbing parts is not the way that it really works. You need to go to a facility beforehand and get quotes.”

And even as technology has allowed for more flexibility, the industry is still one built around large scale manufacturing, making it difficult for hardware startups to get off the ground without big orders right off the bat. “The other big limiting factor is quantity. If you’re below 1,000 units on something, it doesn’t even make sense. You shouldn’t be going to a major factory. It isn’t enough. They’re only starting to get interested at around 5,000 units and above.”

Bogue’s advice is simple. Plan ahead. Speak to manufactures, calculate shipping costs. And failing that, plan on buying a lot of a lot of pizza. “There are alternatives [to traditional manufacturing,” he explains. “Especially now, where you can do mini-maker space assembly lines. You get 50 or 100 friends together, and pay them in beer and pizza.”